At Bay Foam Products Inc., we lead the industry in custom polyethylene foam extrusion. We engineer profile shapes to meet the diverse needs of packaging, OEM, insulation, recreation, and expansion joint applications. Our state-of-the-art, 60,000 sq ft facility in Phoenix, Arizona, features multiple extruders and comprehensive converting/fabrication capabilities, all while prioritizing environmental responsibility. Let’s connect and discuss your custom profile requirements.

Formulations Of Polyethylene Foam

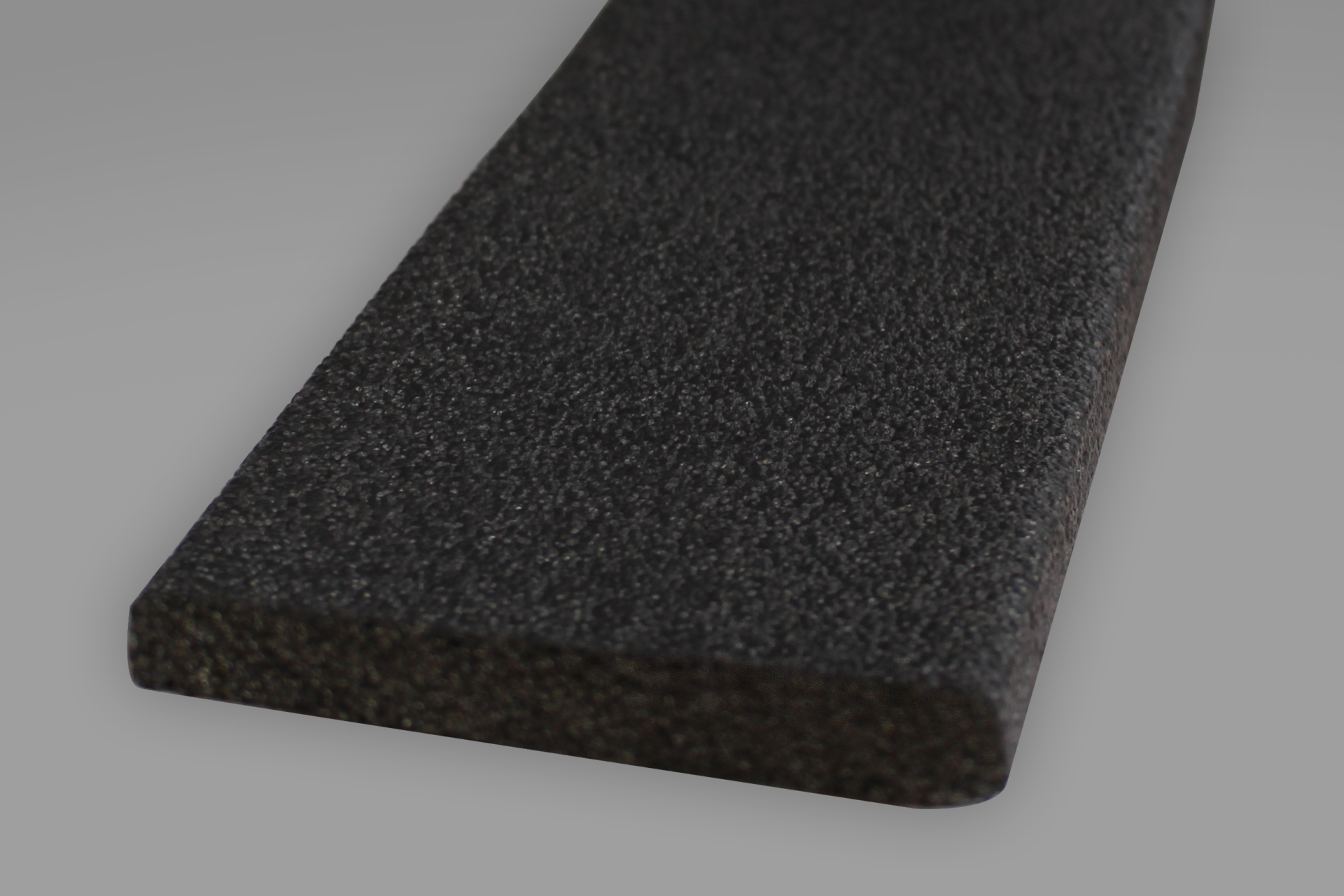

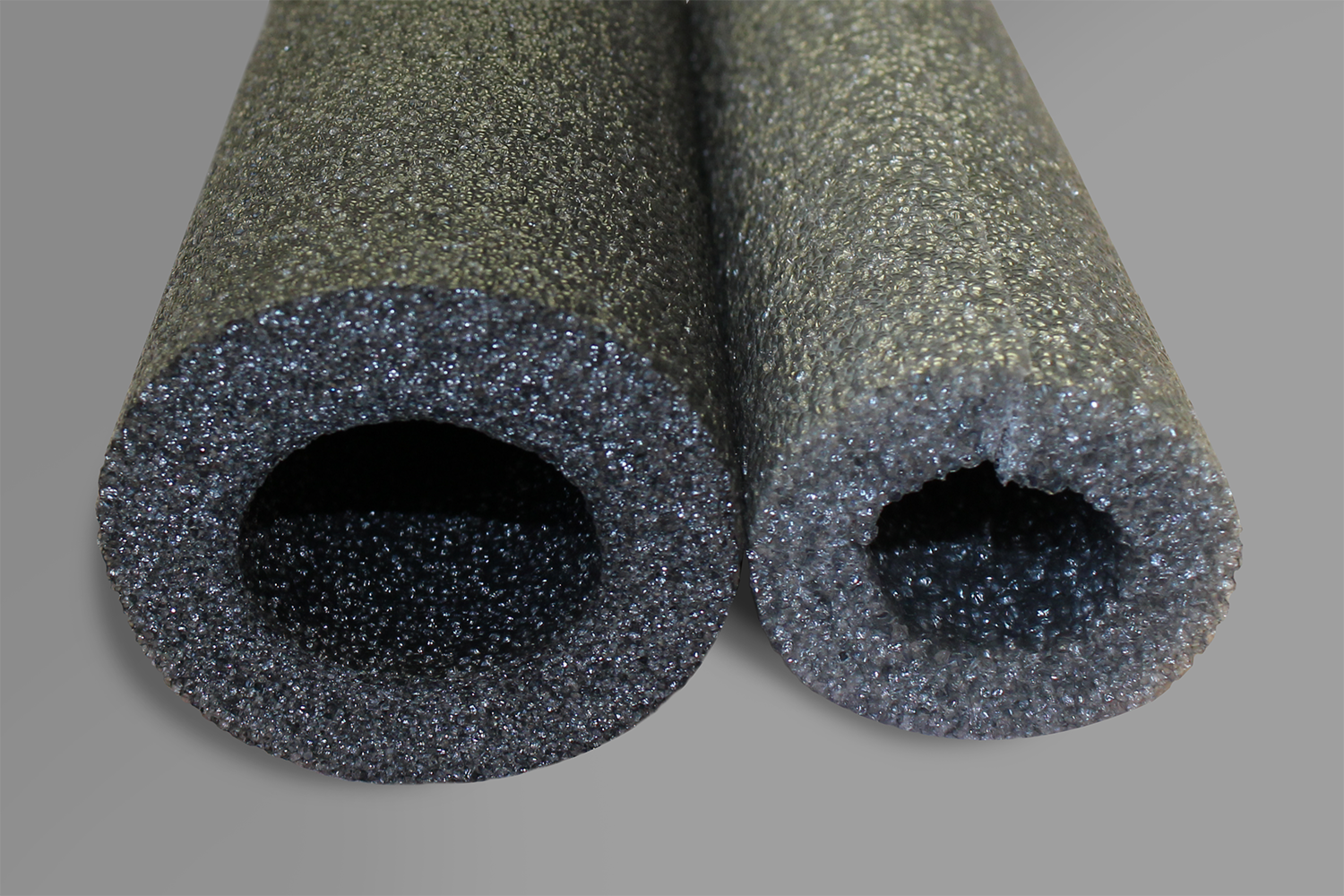

Closed Cell:

Polyethylene foam with a closed cell structure with a water resistant outer skin. Made in various densities, this material can be produced from soft to firm.

Open Cell

Polyethylene foam that is of bi-cellular nature. The majority of the foam is open cell, with a water resistant outer skin. This material is non out-gassing.

Density Range Is 1.5 To 2.5 Pcf.

Higher densities may be achieved. Please contact for details.

Anti-Stat

Closed-cell anti-static foam provides protection for static sensitive materials, such as electronics.

UV Stabilizers

Polyethylene containing UV inhibitors, making it more resistant to harmful UV rays.

Fire Retardant

Polyethylene foam containing fire retardant additives to conform with ASTM E84 25/50 flame/ smoke rating.

Elastomers

We have many elastomer additives available to make any of our products have higher tensile, break strength, resiliency, and softness.

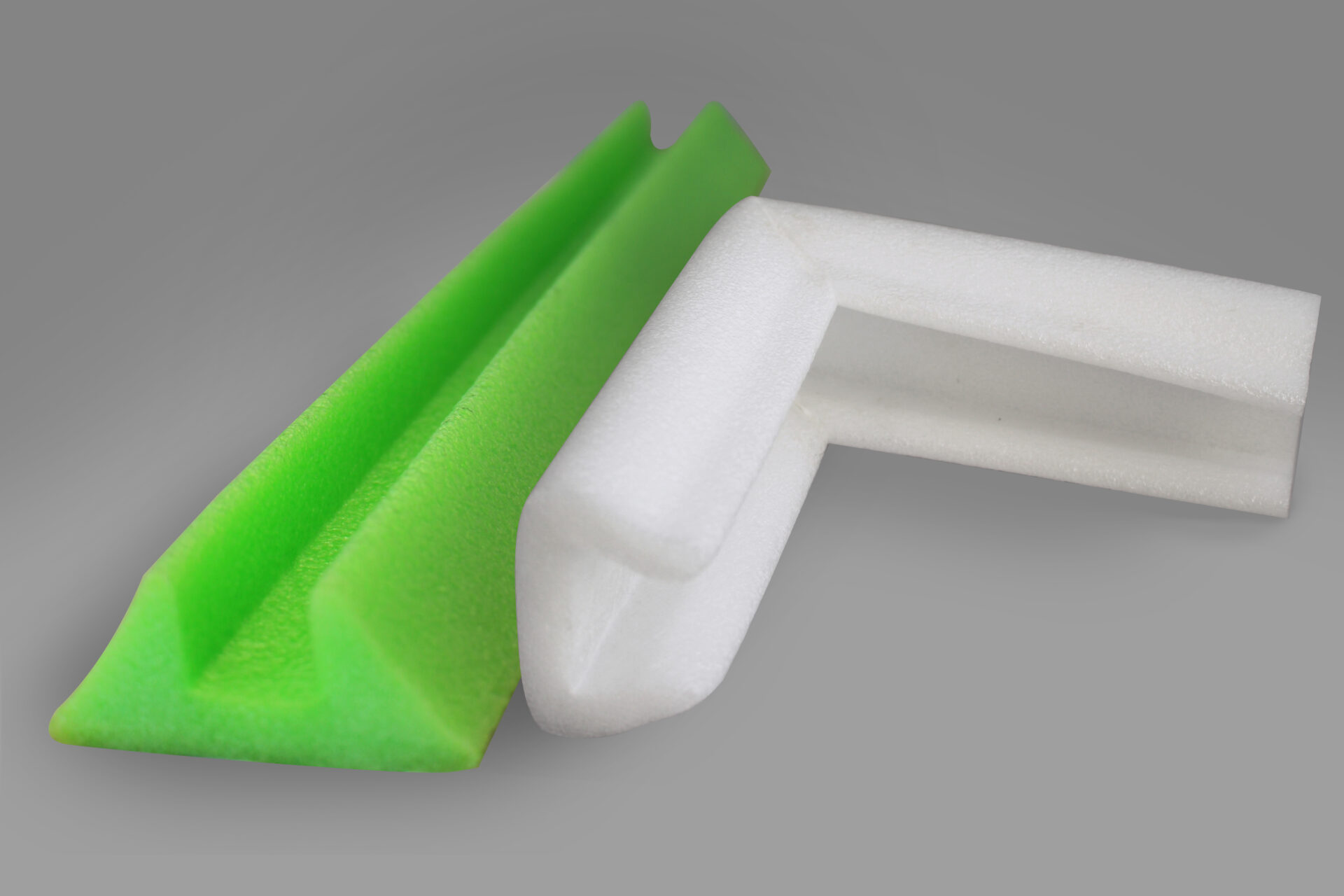

Wide Variety Of Colors

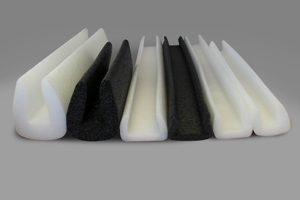

Shapes

- U Channels

- Rounds

- Planks

- W’s (or E’s)

- Squares

- Custom (any 2 dimensional concept)

All foam product profile design and most die manufacturing is accomplished in house.

Off-line converting is accomplished on site.