Denver Foam®

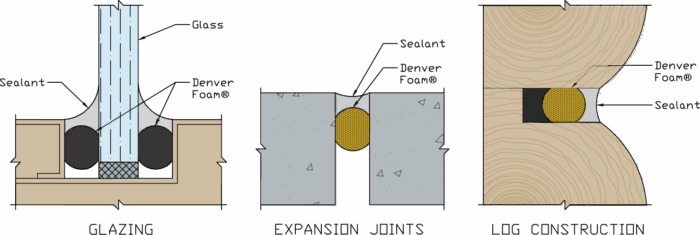

Denver Foam® is an open cell polyurethane backer rod serving as a backing for elastomeric and other applied caulking sealants.

Denver Foam® controls the amount of sealant required and depth of the installation. Also, it forms the correct hour glass shape of sealant, assuring the contractor and owner the best adhesion and cohesion configuration possible.

Specific Uses:

For use in expansion/construction joints in concrete and precast concrete walls, floors, partitions, bridge construction, parking decks, curtain walls, glazing, log home construction, highway construction, and pavement maintenance.

New highway construction and pavement maintenance can be installed with Denver Foam®. Denver Foam® can withstand the temperature of hot pour sealant in maintenance work. Denver Foam® is an open cell backer rod allowing air to reach both sides of sealant, assuring you the required complete cure.

Most of these joints are saw cut and approximately 3/8″ wide. The design depth keeps the sealant below traffic contact and vacuum lift created by fast moving vehicles.

Limitations:

Whatever restriction the Sealant Manufacturer places on his product, the same will apply to Denver Foam®.

Composition And Materials:

Denver Foam® is continuous lengths of flexible, round, fabricated open cell polyurethane. It is yellow in color and available in a wide range of diameters.

Packaging:

Both Mini Bags and Master Bags are compressed into Super Bundles for shipping. Each individual size is color coded for identification, storage and ease of distribution to customer.

Technical Data

Denver Foam® is chemically inert and resists oil, gasoline and most solvents. The material is odorless and will not stain. The open cell construction eliminates the out-gassing and cold flow problem associated with closed cell polyethylene Backer Rods. The sealant also has the benefits of a 2-sided cure.

Select a Denver Foam® size large enough to absorb the pressure during sealant tooling. The open cell structure of Denver Foam’® allows the installer to stretch the rod if the joint narrows (90% elongation). There are no gas cells to rupture.